Thursday, 25 April 2013

LIST OF BASIC SKILLS CAD By; Budi Maryanto, ST

CAD software offers capabilities - basic skills, which are needed to produce the image documents. Here are some of the things the author, which became the basis of the ability of CAD.

1. Ability to Draw construction lines in each room that fits through any point, at any angle and produces

a straight line, tangent to one or more arches

2. The ability to draw any type of line, such lines appear, central line, an invisible line or the line of pieces

3. The ability to draw circles and arches using a variety of sizes, with the size of the specified data entry.

4. The ability to make a cross on the line within the limits specified

5. The ability to create a scale or set a new scale in a variety of objects in images from a document

6. Ability to count or make a list of data with appropriate graphical construction, such as the distance of

an object image, or the corners with precision.

7. The ability to produce a collection of elements forms the basis for publishing or copying images

8. The ability to move elements of the image to each new position. Repair or replace the extras in a saved

document

9. The ability to examine all or remove portions lines, curved lines or any form of the basic elements of

an image. Fixing dimensions

10. The ability to create a shadow glass or produce symmetrical forms

11. The ability to provide a composite measure or base unit

12. The ability to create an image with a record label and making the title box and a list of materials

13. The ability to store all images or parts of images to use in other documents and in other formats.

14. The ability to create three-dimensional images of the projected image in three directions

15. The ability to generate orthografis projection of a three-dimensional model of the image

16. The ability to take and use images that have been saved.

However, the software programmers (software) is fixed and increase the ability of the software (software) CAD.Misalnya, many new program offering three-dimensional capabilities with highly sophisticated, on the operating system window.

Hopefully this can be useful for anyone, who wants to install a CAD system, with respect to the basis of the ability-Traffic CAD system

Saturday, 20 April 2013

SETTING THE NEED FOR CAD SYSTEMS By BUDI M, ST

Which should be considered in the selection process is the CAD system is needed to determine whether CAD systems. Prospective users of CAD systems that have the potential for use should confer to determine how, when, where, how many CAD systems that will be used and whether the CAD system will work effectively and efficiently in terms of cost and operation.

example CAD systems, is Auto Cad 200

No doubt, you will hear a lot of statements about the productivity of the CAD system. Productivity CAD system however will depend on the technical operations. The first company to introduce and use a CAD system is the maker of electronic equipment. They get the experts in the field of equipment electronic images always draw a lot of symbols and also hardware standards using certain symbols. It is much less effective and efficient in drawing. A lot of time is wasted, because drawing all things that have been drawn. You can be sure that the CAD system will save 50 percent of the time making the picture than the use of the system biasa.Perlu note that only CAD system requires drawing once, although at the outset may take a long time rather than drawing on the drawing board. But after that, you just need to call the information in the data storage, and the system will do the CAD drawing with a very high speed. In this section a very clear advantage CAD system.

Tuesday, 16 April 2013

CHOOSING A CAD SYSTEM by Dian Pramesti

Due to the number of manufacturing computer equipment continues to increase, then there is a cost reduction in the use of CAD systems. Some existing CAD systems may only traits needed to draw and produce two-dimensional objects, while for the other systems have the ability to produce three-dimensional pictures of objects. The CAD system makers always want to improve new functions or a CAD system which has undergone improvements that may not be in get on other systems. Almost every day the computer industry announced progress in the development of CAD systems.

Because of the new CAD system is generally much easier to operate, the words "user friendly" is often used by the CAD system makers to promote their systems, and there is a tendency to exaggerate the results of a particular CAD system.

A prospective user must review the statement of program makers CAD system to the existing doubts in his heart proved, the fault of the program you select a CAD system can be misleading and disappointing and will add to the cost of the company. Unfortunately a lot of companies who already bought a CAD system to get CAD system is that it does not work as well as the company expected

Before buying a CAD system, a careful planning must consider this carefully. The plan is divided into five stages

1. Arrange the need for CAD systems

2. Investigate and select traits yamg CAD system in accordance with the requirements

3. Ask the CAD system demonstration

4. Revisit and rethink the CAD system chosen

5. Select, purchase, and install CAD system

Sunday, 14 April 2013

Computer Engineering Structures

A. Not Just A Tool

Which means that the computer is a tool that counters the first

developed for the fields of science and engineering. Only now has

growing increasingly distant, not only counters, but also writers,

painter, and entertainers with video and sound governance, as well as others.

Associated with construction or structural engineering, or rather structural

Computer engineering is the main task of the counter as

The initial purpose tools created, that of the origin of the word to compute.

However, in contrast with a previous count, the computer turns

change the mindset of the workings of engineers in performing structural analysis.

If the previous tradition, in order to understand the behavior of structures with

true, it must understand the methods of calculation manual

done, but with the availability of computers for analysis of the structure, then

without knowing the methods used, engineers can easily and

quickly obtain the desired results. In addition, various structural models

can easily be made, including the necessary mathematical manipulations.

Even so, there is no guarantee that it all makes

engineers can understand the behavior of the actual structure due to the

need to

(a) understand the basic assumptions of the analysis,

(b) understand the behavior of the structuretrue;

(c) able to model the structure and validation results.

To the field of computer engineering is a very useful tool, for

competent users, it can produce a deeper understanding

about the field of engineering problems, in which traditional techniques

previously unable or difficult to get.

B. Basic Principles of Structural Modeling

Modeling the structure of data is numerical (mathematical) represent

real structure is used as input computer data. MacLeod (1990)

should propose the structure modeling are:

1. Do not be too complicated than necessary. If the model can be made

simple but representative, then generally it will be useful.

2. In relation to the above, in modeling sometimes need some

stages of the model. There is a whole (macro model) and other

in certain parts of the course but more detail (micro-models). Do not

willing to make the overall model accuracy

same for every desired detail

3. Is simple model but still representative, it is necessary to know

behavior of the real structure. What factors are primary, secondary or

can be ignored. There is no guarantee that a lot of factors, the results

the better (lower bound theorem). Example, if the calculated bending deformation

the truss structure (truss), the trunk needs to size

are more likely to withstand axial and bending at the same time (more wasteful).

4. Do not immediately believe the computer output, unless it has been

validation-validation conducted a careful and rigorous (a priori).

5. Although there has been a rigorous validation-validation, do not be too trusting

first. View the assumptions used in the modeling analysis,

whether it is logical and represents real structural conditions (alert).

Use of electronic computers

Use of electronic computer at this point has been completely understandable almost at every stage of engineering, science, commerce, and industry, computers. Computers have changed the accounting procedures and manufacture of products, as well as with the application of techniques. Use of computers into the manufacturing process of making a plan to make an example (prototype), production and marketing, at the present time almost all done with computerization.

The application of engineering in particular is an area that will continue to change as new theories and practices that are more sophisticated berkembang.Peralatan continuously developed and perfected constantly using a computer-based CAD.

CAD-based computer has become an indispensable tool because it is effective and efficient for solving problems in the planning problems of working drawings and pictures samples (prototypes).

New methods for analysis, plan development, creation of engineering drawings with AUTO CAD, engineering problem solving and the development of new concepts in science automation is one example of the effect of the implementation of computers and industrial engineering.

Monday, 8 April 2013

OBJECTS OF ART TO

DATA BASE SINGLE

term of art is the object, using a single CAD data base that is used to plan, create documents, analyze, create shapes. The term of art to objects sometimes used to describe the CAD data base, which is used for various purposes or for the overall purpose

MAKE A SKETCH OF FREEDOM

These ideas are beginning to plan on using a hand sketch on a drawing paper, which aims to bring creative ideas to rencana.Sangat important to do a sketch with hand done quickly without having to use the aid program AUTO CAD.Kemampuan use sketch is one of the best tools to assist in this process.

MODELS ARE GIVEN REASON

After menyeleseikan initial ideas. The best step is the development of design plans at this stage selanjutnya.Pada stage, an engineer will make an image in three dimensions (3D) using rough AUTO CAD program for parametric modeling. Parametric modeling using factor not fixed to impose a three-dimensional (3D). Using parametric models planners prepare preliminary sketches and then give the size and limitations picture images to create a model of a given sense. Then planners can change the dimensions and such restrictions while refining the plan so that the new model does not have to be created on any change of plans. The images of three-dimensional (3D) which is derived by AUTO CAD program can help planners to visualize plans

Prototyping QUICKLY

While finishing ideas about the plan, the engineers often work closely with the manufacture to determine the best way to build and install parts (part) that perlu.Setelah several cycles increased, analyzes and synthesize the best ideas, the images generated by AUTO CAD, ready to be produced. Working system that allows rapid prototyping parts quickly made directly from the model of three-dimensional (3D) generated by AUTO CAD, a mock or trial.

Monday, 4 March 2013

Using Sheet Set Manager To Set Up Projects

One of the most time consuming parts of any project is the initial files setup. When you begin a new job, you need to determine the appropriate sheet size, scale, and orientation of your drawings before you can do anything. Then, you'll need to create the actual plans, create and insert title blocks for each, add view ports, general notes, bar scales, legends and a half dozen other items for each individual type of plan. This is all billable time, since you're doing it for your project, but it's not cost efficientuse of your billable hours. Initial setup of a twenty drawing project can take full day of your CAD staff's time. Each subsequent drawing you add can take an additional hour or more. Do the match on the cost to set up a 100+ drawing set and you can see how quickly budgets can be chewed up, and you haven't even begun the design yet.

Wouldn't it be nice if there was a way to simplify and automate the setup process? That's whereAutoCAD's Sheet Set Manager (SSM) comes in. SSM has been around for a long time but not a lot of firms make use of it and those that do aren't making full use of its functionality. I'll show you how to use SSM to save you tens of thousands of dollars on every one of your projects.

How Sheet Set Manager Works

The idea behind SSM is simple; it's nothing more than a tool palette that resides on the side of your screen with links to all the drawings in your set. Each link in the SSM palette lets you open, plot, change properties, even rename and renumber all the drawings in your set. Each link connects to the layout space of an individual drawing saved to your project. SSM can link to multiple layout tabs within a single drawing as well, but it's not the best method to work with. The simplest, and most flexible, way to work with SSM is to separate your design model and plotted sheets into distinct drawings. Essentially, you're splitting model space and paper space into separate files. This way, you can have one drafterworking the design model, while another is modifying the sheet layout.

In the example above, I right-clicked and chose the PROPERTIES option on the top level of the SSM (where it says: Colts Neck Crossing.) The dialog that comes up give you total control of the title properties for your entire set. For example, if you add three more detail sheets to your set you don't have to go into each one and update the total sheet number, you can simply change the "9" to a "12" in the SSM properties and it updates all plans in the set. It works the same way for all the properties listed above. You add new links via right-click, choosing either an entirely new drawing or to link to the layout of an existing file. The SSM list above was created from scratch in under two minutes.

Determining Perspective on Auto cad 2007

AutoCAD provides several ways to use the tool to determine

point of view as follows:

If you are using AutoCAD 2007 or later release

new, can be directly through the control panel combo 3D

Navigate to the Dashboard.

can also do via the toolbar View as

shown in the following figure.

Drawing Toolbar View

If the toolbar View does not already exist on the screen, show

by placing the cursor on one of the toolbar

that already exist on the screen, press the right mouse button,

then select View from the flyout items displayed.

Determination of point of view is very important in

in the modeling process. Tool to manage the visibility of the

is popularly used, the Isometric view.

To be more clear, look at the description of the form of the picture below.

View 3D Image

Sunday, 3 March 2013

AUTOCAD WS

Description

AutoCAD WS enables you view, edit, and share AutoCAD® drawings with anyone, anywhere using your mobile device. Annotate and revise drawings in the office, in the field, or in a meeting. Work on designs without an internet connection, and easily open DWG, DWF, and DXF™ files directly from email. Simplify design creation, review, and approval using powerful, built-in social design collaboration tools. Unleash the power of AutoCAD design beyond the desktop with AutoCAD WS.

✓View

• Open 2D and 3D DWG drawings uploaded to your free* AutoCAD WS online account

• Work offline, then easily upload changes when you are back online

• Upload and open files directly from email on your device

• See all aspects of your DWG file, including external references, layers, and image underlays

• Use multi-touch zoom and pan to easily navigate large drawings

• Use your device’s GPS to orient yourself within a drawing

Join us on the AutoCAD WS Facebook page: http://www.facebook.com/autocadws

Follow us on Twitter @AutoCAD_WS

Follow our blog for updates: http://www.autocadws.com/blog

Email inquiries to: feedback@autocadws.com

✓View

• Open 2D and 3D DWG drawings uploaded to your free* AutoCAD WS online account

• Work offline, then easily upload changes when you are back online

• Upload and open files directly from email on your device

• See all aspects of your DWG file, including external references, layers, and image underlays

• Use multi-touch zoom and pan to easily navigate large drawings

• Use your device’s GPS to orient yourself within a drawing

✓Edit

• Draw and edit shapes with accuracy using Snap

• Select, move, rotate, and scale objects

• Add and edit text annotations directly on your drawing; no need for paper mark-ups

• Validate distance measurements in the drawing while you are onsite

• Save edits to your AutoCAD WS online workspace, so your drawings stay up to date

• Draw and edit shapes with accuracy using Snap

• Select, move, rotate, and scale objects

• Add and edit text annotations directly on your drawing; no need for paper mark-ups

• Validate distance measurements in the drawing while you are onsite

• Save edits to your AutoCAD WS online workspace, so your drawings stay up to date

✓Share

• Share your designs with others directly from the mobile app

• Add comments and images and invite responses using the Design Feed

• Print remotely from your mobile device using HP’s ePrint & Share service

• Plot your designs to PDF or DWF and share them via email

• Share your designs with others directly from the mobile app

• Add comments and images and invite responses using the Design Feed

• Print remotely from your mobile device using HP’s ePrint & Share service

• Plot your designs to PDF or DWF and share them via email

Join us on the AutoCAD WS Facebook page: http://www.facebook.com/autocadws

Follow us on Twitter @AutoCAD_WS

Follow our blog for updates: http://www.autocadws.com/blog

Email inquiries to: feedback@autocadws.com

* Free products and services are subject to the Autodesk, Inc. terms of use that accompany them.

The Best Hardware Configuration for AutoCAD 2013, Part 4: Processor, Video Card, RAM and Hard Drive

So far in this series, I’ve discussed how to determine if your hardware can handle the AutoCAD 2013 upgrade, how to outline your current and future needs and how to find new hardware if you decide it’s time for a new system. If you are looking for new hardware for AutoCAD 2013, here’s some specific components to look at closely.

The Processor and Video Card

Make sure to focus on the processor and the video card when looking for a new workstation.Especially the processor. This component is the most difficult to upgrade latter on.

A video card is easy enough to change out, but they can be very expensive. If you are working with 3D models and create a lot of renderings, make sure to get a good video card. “Regular” 2D CAD work will also require a good video card. Go through Autodesk’s list. Don’t fall into the trap of getting a gaming card. CAD requirements of video cards are very different from game requirements. CAD is a precision tool. Games are not. Games need speed. CAD needs accuracy.

RAM

RAM is another component that is easy to update later. Make sure you get ECC RAM (Error-Correcting Code Memory). One of the requirements of being a “workstation” is having ECC memory. This type of computer memory can detect and automatically fix common types of data corruption. That means fewer crashes while working in your CAD software!

Each motherboard will carry a certain amount of slots for the RAM chips. Get that number of chips. Each slot has a channel in which it can pump data through. If a slot is empty, then that channel isn’t being used.

Hard Drive

What are you going to do for internal storage? I’m talking about the hard drive. Workstations typically have support for RAID, or Redundant Array of Independent Disks. Essentially this type of storage system has multiple hard drives, each mirroring the other. If one fails the workstation still works because the second drive is still running. It’s automatic and can keep your CAD users working. Of course this will increase cost, but it could prolong the life of your workstation.

How much storage space is enough? If you are storing data files, images, videos, etc. on your network instead of your workstation, then you shouldn’t need much storage. 500 GB should be enough for most systems, probably even 350 GB. Make a list of all of the software programs a user needs, include the operating system, and add up the space needed. Leave room for growth and there you go.

The price of hard drives is always dropping, and the amount of storage space on each drive is always increasing. Getting a little less storage capacity could help reduce cost.

Letter Set on the Command Line

When you work with AutoCAD, you are not out of line

orders. To find comfort in use

AutoCAD, you are given the option to set the command line. you

can be set according to your taste. Please follow the steps

the following:

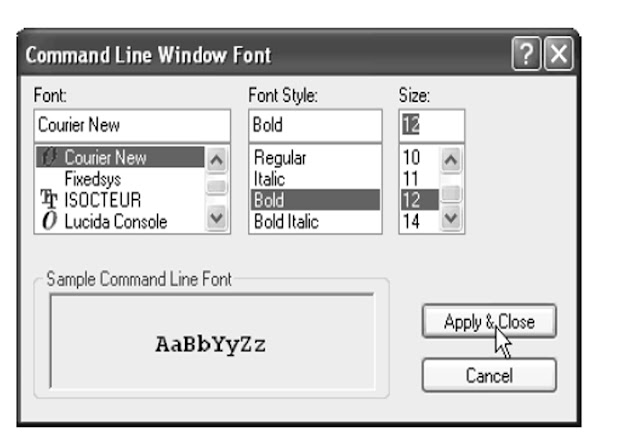

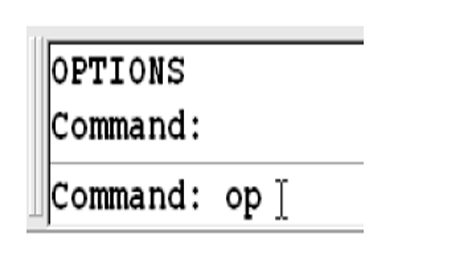

1. Open the Options dialog box, click the Display tab.

2. In the Window Elements area, click the Font button, will appear

dialog box Command Line Window Font.

Fonts Button Image ... the Window Elements

3. Set the text in the command line as per your convenience. For example,

Fonts are used to set the font. Font Style set

Size set the font style and font size.

Picture dialog box settings on the Command line

4. Press the Apply & Close and press OK on the Options dialog box.

Drawing Text on a Command Line after modified

Saturday, 2 March 2013

Mechanical Drafting and Design - CAD

Are you fascinated by mechanical design? Are you creative and artistic? If so, a career in mechanical drafting and design might be for you, and the following information can help you get started.

Is Mechanical Drafting and Design for Me?

Many mechanical drafting and design workers use computer-aided design (CAD) software to prepare technical plans and drawings. Some drafters, also known as draftsmen, CADD operators or AutoCAD designers, have the ability to make designs and drawings through software programs. These programs allow you to save or print your work for future reference. You can even input your work into a main manufacturing system for the production of products or devices.

Although CAD is used most often in the drafting field today, you should still know how to create designs manually. Your job will be to create drawings exhibiting the mechanical aspects and construction of many types of mechanisms. These drawings detail measurements and other specifications used in products and machinery.

According to the U.S. Bureau of Labor Statistics (BLS), employment of mechanical drafters was expected to decrease one percent from 2008-2018 (www.bls.gov). However, employment opportunities were projected to be good for those who possess a minimum of two years of formal training. In May 2010, mechanical drafters earned an average wage of $51,200, noted the BLS.

How Do I Work in Mechanical Drafting and Design?

Employers seek aspirants who have had formal academic training, preferably in areas of drafting. You can obtain formal training through mechanical drafting and design programs. Undergraduate certificate programs and associate degree programs, such as an associate degree program in mechanical computer-aided designor an associate degree program in mechanical drafting, are commonly available. You can find these types of programs at technical colleges and community colleges. Courses might include manufacturing materials, engineering processes, sketching, production techniques and CAD. Online mechanical drafting programs are also available.

As a graduate of a mechanical drafting technology program, you might begin work as a detail drafter. You might work in the department of engineering at a product development and manufacturing plant. You may find employment in other places like an engineering company, electro-mechanical firm or manufacturing facility. After you gain some experience, you could move on to an assistant engineer position.

The American Design Drafting Association (ADDA) offers voluntary certifications for drafters (www.adda.org). Be prepared to complete a mechanical exam application. Passing this, you can reach the Certified Design Drafter designation with a specialization in mechanical drafting.

rafting Technology: AutoCAD Bachelor's Degree

Drafters help design everything from buildings to shoes. With the advent of and reliance on computer technology, most drafting is done using computer software. This is referred to as computer-aided drafting (CAD) or computer-aided drafting and design (CADD). One of the programs used in CAD is AutoCAD, which is a brand name. Focusing on 2-D and 3-D design and drafting, AutoCAD is an integral part of drafting technology. Read on to learn more about a bachelor's degree dealing with AutoCAD. Schools offeringAutoCAD Drafting & Design Technology degrees can also be found in these popular choices.

What Can You Tell Me About a Drafting Technology AutoCAD Bachelor's Degree?

Degree programs in drafting technology don't necessarily specialize in AutoCAD, but many of them utilize it as the main CAD platform. AutoCAD is the most prominently used software in the practice of computer-aided design. You can most often locate AutoCAD instruction in CAD courses within an associate's degree program in drafting technology. Though rare, there are schools that offer bachelor's degree programs in design and drafting technology.

You might use the database maintained by the National Center for Education Statistics (NCES) to help you locate a drafting technology degree program that contains AutoCAD instruction. Also, the American Design Drafting Association (ADDA) maintains an online directory of accredited schools that may offer AutoCAD instruction. You may also find the database of accredited programs maintained by the Association of Technology, Management and Applied Engineering (ATMAE) to be useful in your search.

What Can I Expect in a Program?

You can earn an Associate of Applied Science or Associate of Science in an area such as drafting technology or design and drafting by way of a program that consists of about 60 credits and can last two years. You may have an opportunity to specialize in an area such as civil, mechanical, electrical or electronic drafting.

If you decide not to enter the workforce immediately, you may have the opportunity to transfer credits earned toward a bachelor's degree program. A Bachelor of Science program generally consists of about 120 credits and takes four years to complete. Completion of a program may qualify you to become a civil, mechanical, electrical or industrial engineer.

Typical AutoCAD-related courses you might encounter include residential drafting and design, 3-D modeling, CAD, engineering technology, product design, architectural drafting, mechanical drafting, industrial design and graphics. You may have the opportunity to complete one or more internships at a school-partnered, independent firm.

What Can You Tell Me About Online Opportunities?

Though opportunities are rare, you can find schools that allow you to complete drafting technology programs online. More commonly, schools offer programs leading to CAD or AutoCAD certificates. In addition, Autodesk, the parent company of AutoCAD, offers many online courses in various applications and versions of AutoCAD.

What Are Some Employment and Wage Projections?

The U.S. Bureau of Labor Statistics (BLS) has made employment projections for the 2008-2018 (www.bls.gov) period. The BLS made it a point to mention that being well-trained in CADD is an important factor that can affect your employment and advancement potential.

If you decide to enter the workforce after earning an associate's degree in drafting technology, you'll find that opportunities for drafters in general will increase an average of four percent over that 10-year period. Civil drafters lead the projection at nine percent, while electrical or electronics drafters come in at a one percent increase. Positions for mechanical drafters should actually decrease one percent by 2018.

Should you go on to earn a bachelor's degree, you'll find the situation to be quite different. Opportunities for electrical and electronics engineers and mechanical engineers will only increase one percent and six percent, respectively. However, opportunities for industrial and civil engineers will increase 14% and 24%, respectively.

In 2010, the BLS determined mean annual wages. Civil drafters came in at $48,740, mechanical drafters at $51,200 and electrical drafters at $55,960.

The mean annual salary for industrial engineers was determined to be $78,430. Civil and mechanical engineers came in at $82,230 and $82,480, respectively. Electrical and electronics engineers topped the list at $87,770.

setting AutoSnap

Bahasa Indonesia

Inggris

Arab

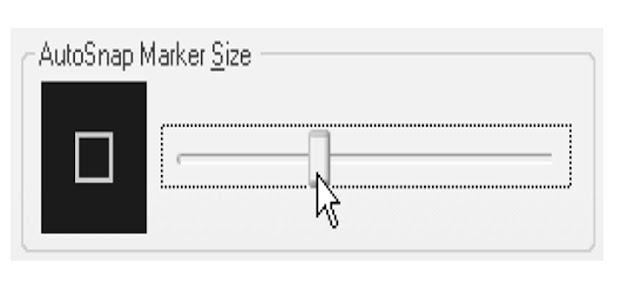

but you need to set the size to make it more effective.

Follow the steps below:

1. Open the Options dialog box, click the Drafting tab.

2. To change the size of the marker in the area Autosnap Marker

Size, there is a slide to adjust the size. Scroll to size

desired.

Area AutoSnap Marker to set Snap

3. Click OK to finish.

Friday, 1 March 2013

There's Always Something New in the Year

by Michael Beall

None of us knows what's in store for 2013, but one thing we DO

know, is that there's always something new to learn about. I hope this

finds you all well and looking forward to the new things that lie ahead

in your respective areas of expertise.Many years ago when I was working with Hugh Bathurst and presenting the 'Mastering Today's AutoCAD' series around the USA, I met folks who used AutoCAD in some very unique industries; fire plug design, rail car design, and prison cafeterias were some of the ones that come to mind. Absolutely fascinating and very 'new' to me. If you work in an industry with similar unique drawing requirements, I would be interested in seeing a small sample drawing of your work.

This month, ask yourself the following questions, and then see if your answers are the same as what I came up with. You may just find something new!

…Do you know how to add a dimension to a 3D object?

…Were you aware of the Layer option when you use the Offset command?

…Have you ever noticed the background mask in Mtext needs adjusting?

…When you plot a Window from Model space, do you know how to estimate the plot scale?

Thank you all so very much for your continued support of Michael's Corner and CADTutor, and we hope you have a fabulous New Year!

As always, if you would like to be notified when Michael's Corner is posted each month, just subscribe to our mailing list and we'll be sure to let you know when this critter comes online. There's well over 2,000 of you now and it is an honor to be looked upon as a resource for your AutoCAD well-being. You can also keep in touch using the RSS feed. If you would like to contact me directly, you can do that also.

Blessings to one and all,

Michael

Thursday, 28 February 2013

Coordinate system in AUTOCAD using 2 types, namely World Coordinate System (WCS) and the User Coordinate System (UCS). AUTOCAD as used by default is the WCS (World Coordinat System), which is the coordinate system with axes X, Y, Z in which each of the coordinate axes intersect at the point (0,0) or the point of origin, the positive direction of each axis is represented by the direction of the arrow. while UCS is a coordinate system that is devoted to the user and can be changed positions origin point (0,0,0) in accordance with user commands. This system makes the depiction of 3D.

There are several kinds of commands coordinate system AutoCAD 2002 among others,

Cartesian

Cartesian coordinates of the object can be used for two-dimensional (2D) and three dimensional (3D). Based on the Cartesian coordinate axes x, y, z. Is as follows:

(X), (y) and (x), (y), (z)

POLAR

Polar coordinates can only be used on two-dimensional objects. Polar coordinates are used to specify a point by combining distance and angle. Is as follows:

(Distance) <(angle)

RELATIVE

Coordinates are relative to the coordinate system beracuan at the end point of an object that has been created. In the use of relative coordinates assistance @ symbol used is as follows

@ (X), (y) = for 2D objects and cartesian berkoordinat

@ (Distance) <(angle) = for 2D objects and patterns berkoordinat

Coordinates System AUTOCAD 2002

Coordinate system in AUTOCAD using 2 types, namely World Coordinate System (WCS) and the User Coordinate System (UCS). AUTOCAD as used by default is the WCS (World Coordinat System), which is the coordinate system with axes X, Y, Z in which each of the coordinate axes intersect at the point (0,0) or the point of origin, the positive direction of each axis is represented by the direction of the arrow. while UCS is a coordinate system that is devoted to the user and can be changed positions origin point (0,0,0) in accordance with user commands. This system makes the depiction of 3D.

There are several kinds of commands coordinate system AutoCAD 2002 among others,

Cartesian

Cartesian coordinates of the object can be used for two-dimensional (2D) and three dimensional (3D). Based on the Cartesian coordinate axes x, y, z. Is as follows:

(X), (y) and (x), (y), (z)

POLAR

Polar coordinates can only be used on two-dimensional objects. Polar coordinates are used to specify a point by combining distance and angle. Is as follows:

(Distance) <(angle)

RELATIVE

Coordinates are relative to the coordinate system beracuan at the end point of an object that has been created. In the use of relative coordinates assistance @ symbol used is as follows

@ (X), (y) = for 2D objects and cartesian berkoordinat

@ (Distance) <(angle) = for 2D objects and patterns berkoordinat

What is AutoCAD Customization?

AutoCAD customization can be divided into two parts: Non-programming customization & Programming customization:

Non-programming customization consists of:

- User interface customization by adding specific required toolbars, menu bars & palettes

- Creation of customized hatch

- Block library development

- Creation of customized linetypes & shapes.

Programming customization consists of:

Addition of your own commands to AutoCAD, which will perform the activities desired by you. Some of the examples of AutoCAD programming is as follows:

- Design & drafting automation

- Automatic drawing generation based on design calculations

- Automatic production drawing generation

- Automatic bill of material generation

- Automatic quotation preperation

- Automatic CNC machine code generation

Why customize AutoCAD?

- The main reason for customization is time saving. Time wasted on repeated type of work can be saved & used for other more productive work.

- Accurate output generation.

- Quick response to customer queries.

Non-programming customization consists of:

- User interface customization by adding specific required toolbars, menu bars & palettes

- Creation of customized hatch

- Block library development

- Creation of customized linetypes & shapes.

Programming customization consists of:

Addition of your own commands to AutoCAD, which will perform the activities desired by you. Some of the examples of AutoCAD programming is as follows:

- Automatic drawing generation based on design calculations

- Automatic production drawing generation

- Automatic bill of material generation

- Automatic quotation preperation

- Automatic CNC machine code generation

Why customize AutoCAD?

- Accurate output generation.

- Quick response to customer queries.

Subscribe to:

Comments

(

Atom

)